Offsite Technology and The Skills Gap in Construction

Offsite Technology and The Skills Gap in Construction

Construction’s future, like so many other sectors, lies within digital. Sophisticated data analysis and digital management are factors that are permeating the profession, from the top down – and from the bottom up.

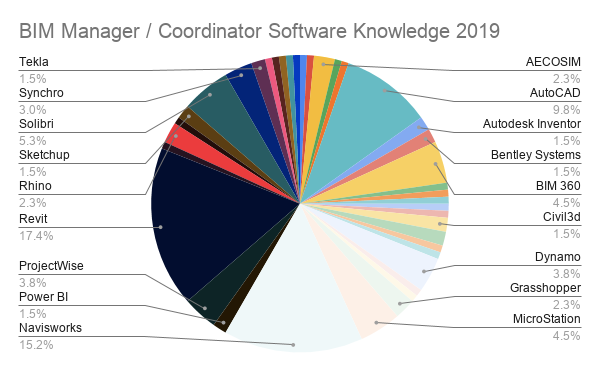

The below table details our findings on the software skills required for BIM Coordinators and managers across fifty jobs. The amount of software available and the digital management skill requirements raise questions around the potential of a skills gap. Now is the time businesses should be investing in skills.

As Jackie Maginnis, chief executive of MPBA noted, in the chancellor’s 2017 budget announcements, there was a ‘presumption in favour’ of offsite construction by 2019 across all suitable capital programmes. Previously, offsite construction had been considered more of an extension to existing projects; they were by no means seen as integral as they are to today’s construction projects.

With further adoption of offsite construction methods, so too comes a more developed involvement of technology – especially when it comes to digital design and implementation. Due to this, the lines between manufacturing, engineering and construction are becoming further blurred. With the inclusion of broader skills needed within the construction sphere, it is unsurprising to see it attracting – or needing to train and attract – a new group of skillsets.

citb – in unlocking construction’s digital future – stated that construction’s people need to be able to:

- think creatively about problems and their solutions

- understand how to use digital tools

- assess which tools to use in which circumstance

- manage the data that flows to and from the use of these tools.

These skills are especially necessary when we see the number of roles within Building Information Modelling (BIM) continue to grow; Go Construct predict that in the next five years we expect 232,000 jobs to be created within the industry. They too agree that as the nature of construction continues to change, the need for more extensive skillsets, perhaps even cross-sector, are needed.

The worry, as Richard Anderson points out in his article, is that if businesses aren’t able to adopt these technologies and breach the skills gap within their organisation, they run the risk of losing out to more prominent players. Those at the top of businesses do not just require skills such as problem-solving, data management, and broader digital literacy, but those on-site must also be equipped to understand and manage data flow.

Smaller firms may be the ones to take the brunt of these changes – the ability to hire those with technical experience will be more difficult. It may require a whole new way of looking at construction; a construction industry which becomes more synonymous with IT and Math capability over manual labour. Collaboration with schools and apprenticeships are a must.

Why Businesses Should Invest in Both Offsite Technology and Skills

The adoption of new skills is just as important as the adoption of new technology that increased offsite construction and design is bringing with it.

Offsite design and construction, in tandem, offer:

- the alleviation of safety concerns

- the mitigation of on-site construction skills gap

- time compression

- improved on-site safety

- increased productivity

- increased sustainability

- clear visualisation of quantitative data.

Through BIM, offsite construction offers greater control and predictability of build. One of the strongest aspects of embracing technology during the design and construction phase is client buy-in. Client’s can join these visualisations to become part of the construction journey. They can invest where they choose, thus speeding up the concept stage of projects. Should a brief change – the offsite design offers the ability for instant adaptation.

The Future is Modular

The technology that BIM brings allows testing within virtual environments. This will give access to information around on-site assembling and modelling. This is just as important to offsite manufacturing as it is to design and architecture.

With these advancements, offsite manufacturing is heavily adopting Modular construction. This style of construction has already made remarkable impacts on reducing costs and already makes up 60 – 70 per cent of all offsite manufacturing. It also offers a series of benefits, including:

- environmental friendliness

- maximised sustainability

- heavily reduced building costs

- faster build times.

With such a high demand for housing needed, and the construction industry primarily serving the government and the wider public sector, it’s hard to ignore the predicted 210,000 required houses per year. The impact offsite construction and digital design could have on the production cost, and capability is substantial. The need for technology adoption and investing in skills cannot be ignored.

Can The Industry Afford Passing Up On This Tech and The Skills it Requires?

Mark Beacom, in his article about transforming skills sets within construction, mentions how the new skills demands will see unique and more specialised roles to come from the sector. There will need to be clear and well-devised upskilling strategies in place to make sure that change is implemented throughout workforces.

Top recurring software skillsets needed source: indeed.co.uk (2019) BIM Manager/Coordinator roles.